Toroidal Core

Toroidal core are traditional round-shaped powder cores which formed by distributing air gap in ferrous alloy powders for low losses at high frequencies. Small air gaps distributed evenly throughout the cores increase the amount of Direct Current (DC) that can be passed through the winding before core saturation. This is the most popular type cores and widely apply in electronic power supply industry. There are different core sizes from 9.6mm (OD) to 165mm (OD), while permeability from 19um~173um according to types.

-

Major Types:

MPP Cores : Ni-Fe-Mo alloy

High Flux Cores : Fe-Ni alloy

Sendust Cores : Fe-Si-Al alloy

Mega Flux Cores : Fe-Si alloy

HS Cores: : HF-HP alloy

HP Cores: : Fe-Si-Al alloy

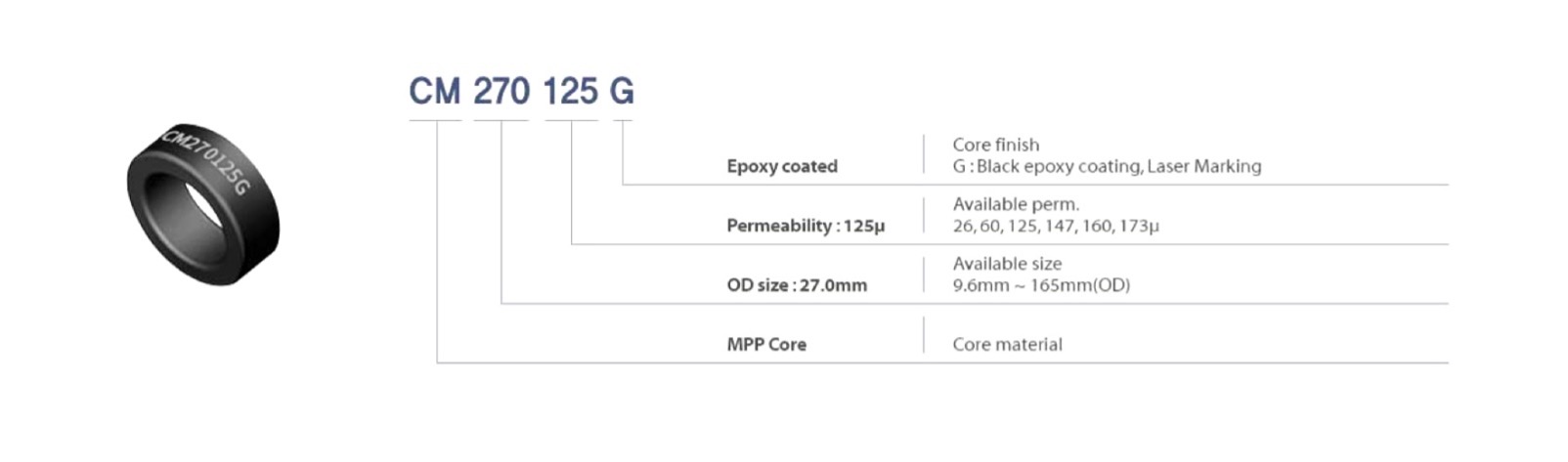

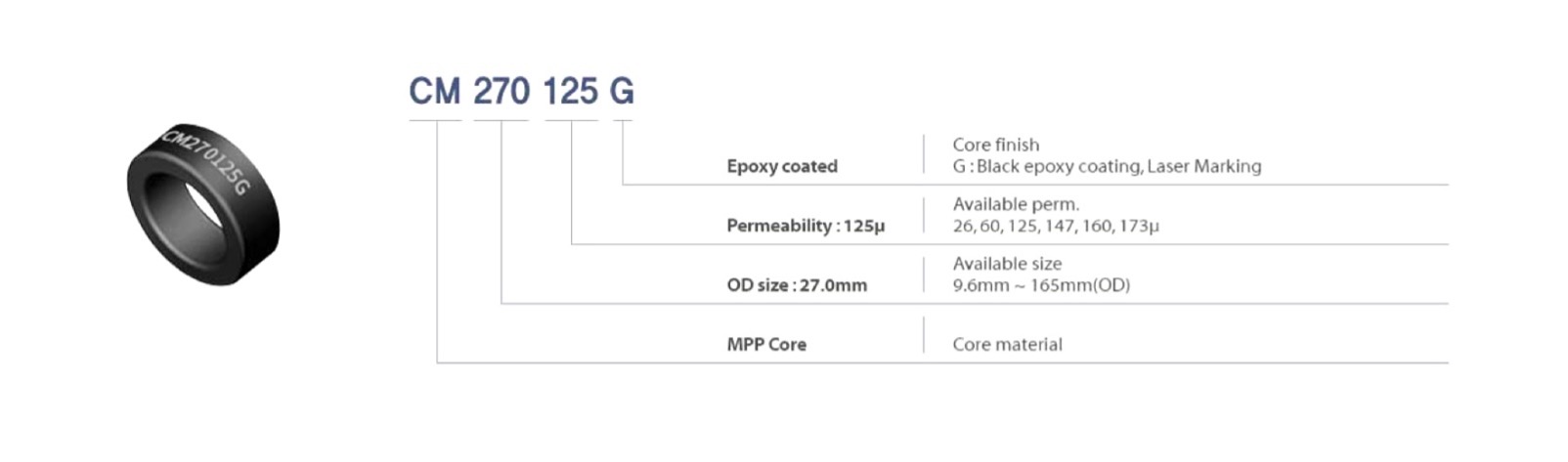

MPP Cores

-

Characteristics:

Ni-Fe-Mo alloy

Low core los and high permeability

Excellent temperature and inductance stability

under high DCB conditions.

Variety of sizes and permeability.

-

Applications:

DC output inductors, High Q filter, Loading coils, EMI/RFI filter, aircraft industry.

| Part No |

Nominal Inductance(nH/N²) |

Path Length (cm) |

Cross Section Area (cm²) |

Dimensions(mm) |

| Before Finish Dimensions |

After Finish Dimensions |

| OD(mm) |

ID(mm) |

HT(mm) |

OD(mm) |

ID(mm) |

HT(mm) |

| 26 |

60 |

125 |

147 |

160 |

173 |

MAX |

MIN |

MAX |

MAX |

MIN |

MAX |

| CM096 |

11 |

25 |

53 |

63 |

68 |

74 |

2.18 |

0.0752 |

9.65 |

4.78 |

3.18 |

10.29 |

4.27 |

3.81 |

| CM097 |

14 |

32 |

66 |

78 |

84 |

92 |

2.18 |

0.0945 |

9.65 |

4.78 |

3.96 |

10.29 |

4.27 |

4.57 |

| CM102 |

14 |

32 |

66 |

78 |

84 |

92 |

2.38 |

0.1 |

10.16 |

5.08 |

3.96 |

10.8 |

4.57 |

4.57 |

| CM112 |

11 |

26 |

53 |

63 |

68 |

74 |

2.69 |

0.0906 |

11.18 |

6.35 |

3.96 |

11.9 |

5.89 |

4.72 |

| CM127 |

12 |

27 |

56 |

67 |

72 |

79 |

3.12 |

0.114 |

12.7 |

7.62 |

4.75 |

13.46 |

6.99 |

5.51 |

| CM166 |

15 |

35 |

72 |

88 |

92 |

104 |

4.11 |

0.192 |

16.51 |

10.16 |

6.35 |

17.4 |

9.53 |

7.11 |

| CM172 |

19 |

43 |

89 |

105 |

114 |

123 |

4.14 |

0.232 |

17.27 |

9.65 |

6.35 |

18.03 |

9.02 |

7.11 |

| CM203 |

14 |

32 |

68 |

81 |

87 |

96 |

5.09 |

0.226 |

20.32 |

12.7 |

6.35 |

21.1 |

12.07 |

7.11 |

| CM229 |

19 |

43 |

90 |

106 |

115 |

124 |

5.67 |

0.331 |

22.86 |

13.97 |

7.62 |

23.62 |

13.39 |

8.38 |

| CM234 |

22 |

51 |

105 |

124 |

135 |

146 |

5.88 |

0.388 |

23.57 |

14.4 |

8.89 |

24.3 |

13.77 |

9.7 |

| CM270 |

32 |

75 |

157 |

185 |

201 |

217 |

6.35 |

0.654 |

26.92 |

14.73 |

11.18 |

27.7 |

14.1 |

11.99 |

| CM330 |

28 |

61 |

127 |

150 |

163 |

176 |

8.15 |

0.672 |

33.02 |

19.94 |

10.67 |

33.83 |

19.3 |

11.61 |

| CM343 |

16 |

38 |

79 |

93 |

101 |

109 |

8.95 |

0.454 |

34.29 |

23.37 |

8.89 |

35.2 |

22.6 |

9.83 |

| CM358 |

24 |

56 |

117 |

138 |

150 |

162 |

8.98 |

0.678 |

35.81 |

22.35 |

10.46 |

36.7 |

21.5 |

11.28 |

| CM400 |

35 |

81 |

168 |

198 |

215 |

233 |

9.84 |

1.072 |

39.88 |

24.13 |

14.48 |

40.7 |

23.3 |

15.37 |

| CM467 |

59 |

135 |

281 |

33 |

360 |

|

10.74 |

1.99 |

46.74 |

24.13 |

18.03 |

47.6 |

23.3 |

18.92 |

| CM468 |

37 |

86 |

178 |

210 |

228 |

|

11.63 |

1.34 |

46.74 |

28.7 |

15.24 |

47.6 |

27.9 |

16.13 |

| CM508 |

32 |

73 |

152 |

179 |

195 |

|

12.73 |

1.25 |

50.8 |

31.75 |

13.46 |

51.7 |

30.9 |

14.35 |

| CM571 |

60 |

138 |

287 |

306 |

333 |

|

12.5 |

2.29 |

57.15 |

26.39 |

15.24 |

58 |

25.6 |

16.1 |

| CM572 |

33 |

75 |

156 |

185 |

200 |

|

14.3 |

1.444 |

57.15 |

35.56 |

13.97 |

58 |

34.7 |

14.86 |

| CM610 |

|

192 |

400 |

|

|

|

14.37 |

3.675 |

62 |

32.6 |

25 |

63.1 |

31.37 |

26.27 |

| CM740 |

|

206 |

429 |

|

|

|

18.38 |

5.04 |

74.1 |

45.3 |

35 |

75.2 |

44.07 |

36.27 |

| CM777 |

30 |

68 |

142 |

|

|

|

20 |

1.77 |

77.8 |

49.23 |

12.7 |

78.9 |

48 |

13.97 |

| CM778 |

37 |

85 |

178 |

|

|

|

20 |

2.27 |

77.8 |

49.23 |

15.9 |

78.9 |

48 |

17.02 |

| CM1013 |

40 |

92 |

192 |

|

|

|

24.27 |

2.97 |

101.6 |

57.2 |

13.6 |

103.1 |

55.7 |

14.9 |

| CM1016 |

47 |

112 |

228 |

|

|

|

24.27 |

3.52 |

101.6 |

57.2 |

16.5 |

103.1 |

55.7 |

17.8 |

| CM1027 |

80 |

184 |

384 |

|

|

|

24.27 |

5.94 |

101.6 |

57.2 |

27.2 |

103.1 |

55.7 |

28.5 |

| CM1033 |

94 |

224 |

456 |

|

|

|

24.27 |

7.04 |

101.6 |

57.2 |

33 |

103.1 |

55.7 |

34.3 |

| CM1320 |

|

|

|

|

|

|

32.42 |

5.35 |

132.5 |

78.6 |

20.3 |

134.2 |

77 |

21.7 |

| CM1325 |

68 |

156 |

325 |

|

|

|

32.42 |

6.71 |

132.5 |

78.6 |

25.4 |

134.2 |

77 |

26.8 |

| CM1333 |

88 |

202 |

422 |

|

|

|

32.42 |

8.72 |

132.5 |

78.6 |

33 |

134.2 |

77 |

34.4 |

| CM1340 |

108 |

248 |

518 |

|

|

|

32.42 |

10.69 |

132.5 |

78.6 |

40.6 |

134.2 |

77 |

42 |

| CM1625 |

80 |

184 |

384 |

|

|

|

38.65 |

9.46 |

165 |

88.9 |

25.4 |

167.2 |

86.9 |

27.3 |

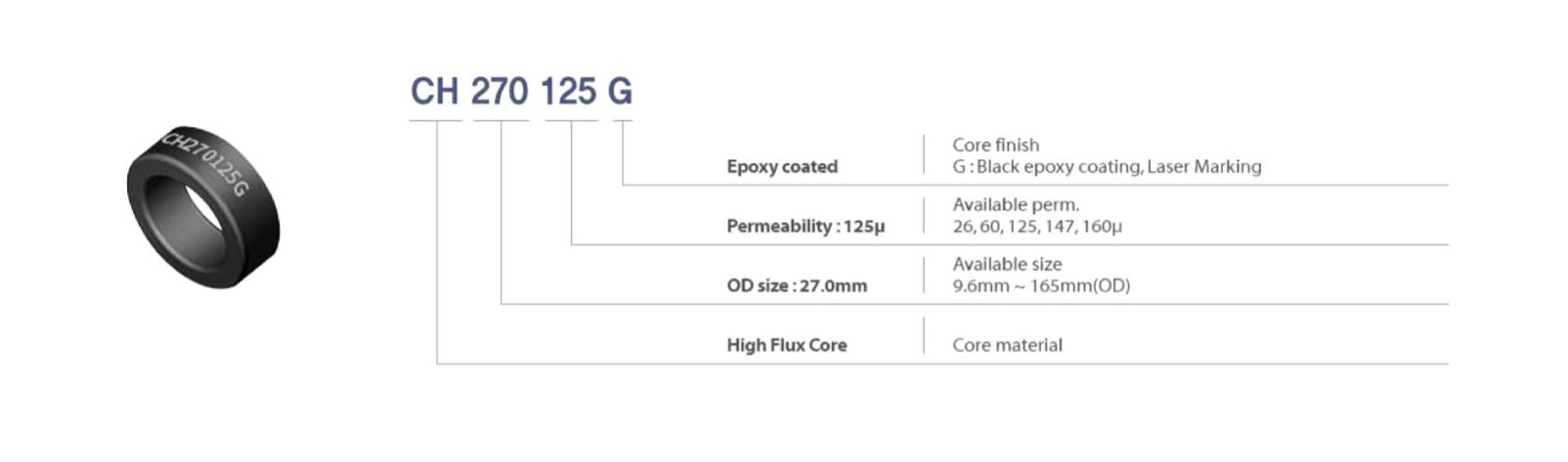

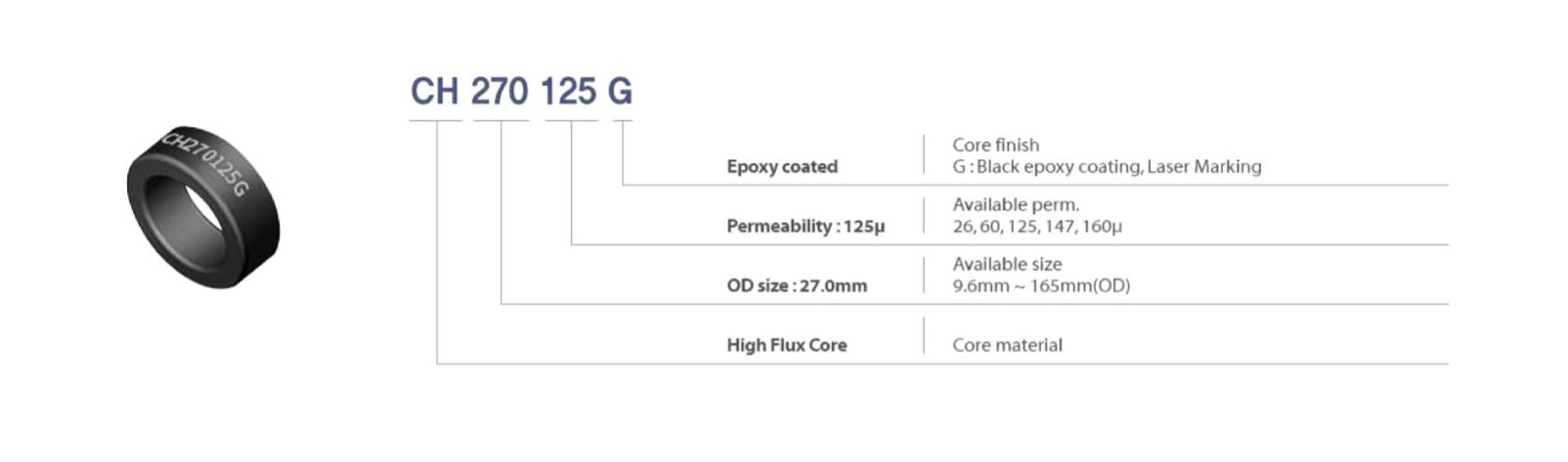

High Flux Cores

-

Characteristics:

Ni-Fe alloy

High energy storage capability (up to 15000 Gauss saturation level)

Excellent DC bias (DCB) and low core losses

Variety of sizes and effective permeability.

-

Applications:

PFC reactors, switching regulator inductors, in -line noise filters, pulse transformers, flyback transformers.

| Part No |

Nominal Inductance(nH/N²) |

Path Length (cm) |

Cross Section Area (cm²) |

Dimensions(mm) |

| Before Finish Dimensions |

After Finish Dimensions |

| OD(mm) |

ID(mm) |

HT(mm) |

OD(mm) |

ID(mm) |

HT(mm) |

| 26 |

60 |

125 |

147 |

160 |

MAX |

MIN |

MAX |

MAX |

MIN |

MAX |

| CH096 |

11 |

25 |

53 |

63 |

68 |

2.18 |

0.075 |

9.65 |

4.78 |

3.18 |

10.29 |

4.27 |

3.81 |

| CH097 |

14 |

32 |

66 |

78 |

84 |

2.18 |

0.095 |

9.65 |

4.78 |

3.96 |

10.29 |

4.27 |

4.57 |

| CH102 |

14 |

32 |

66 |

78 |

84 |

2.38 |

0.1 |

10.16 |

5.08 |

3.96 |

10.8 |

4.57 |

4.57 |

| CH112 |

11 |

26 |

53 |

63 |

68 |

2.69 |

0.091 |

11.18 |

6.35 |

3.96 |

11.9 |

5.89 |

4.72 |

| CH127 |

12 |

27 |

56 |

67 |

72 |

3.12 |

0.114 |

12.7 |

7.62 |

4.75 |

13.46 |

6.99 |

5.51 |

| CH166 |

15 |

35 |

72 |

88 |

92 |

4.11 |

0.192 |

16.51 |

10.16 |

6.35 |

17.4 |

9.53 |

7.11 |

| CH172 |

19 |

43 |

89 |

105 |

114 |

4.14 |

0.232 |

17.27 |

9.65 |

6.35 |

18.03 |

9.02 |

7.11 |

| CH203 |

14 |

32 |

68 |

81 |

87 |

5.09 |

0.226 |

20.32 |

12.7 |

6.35 |

21.1 |

12.07 |

7.11 |

| CH229 |

19 |

43 |

90 |

106 |

115 |

5.67 |

0.331 |

22.86 |

13.97 |

7.62 |

23.62 |

13.39 |

8.38 |

| CH234 |

22 |

51 |

105 |

124 |

135 |

5.88 |

0.388 |

23.57 |

14.4 |

8.89 |

24.3 |

13.77 |

9.7 |

| CH270 |

32 |

75 |

157 |

185 |

201 |

6.35 |

0.654 |

26.92 |

14.73 |

11.18 |

27.7 |

14.1 |

11.99 |

| CH330 |

28 |

61 |

127 |

150 |

163 |

8.15 |

0.672 |

33.02 |

19.94 |

10.67 |

33.83 |

19.3 |

11.61 |

| CH343 |

16 |

38 |

79 |

93 |

101 |

8.95 |

0.454 |

34.29 |

23.37 |

8.89 |

35.2 |

22.6 |

9.83 |

| CH358 |

24 |

56 |

117 |

138 |

150 |

8.98 |

0.678 |

35.81 |

22.35 |

10.46 |

36.7 |

21.5 |

11.28 |

| CH400 |

35 |

81 |

168 |

198 |

215 |

9.84 |

1.072 |

39.88 |

24.13 |

14.48 |

40.7 |

23.3 |

15.37 |

| CH467 |

59 |

135 |

281 |

33 |

360 |

10.74 |

1.99 |

46.74 |

24.13 |

18.03 |

47.6 |

23.3 |

18.92 |

| CH468 |

37 |

86 |

178 |

210 |

228 |

11.63 |

1.34 |

46.74 |

28.7 |

15.24 |

47.6 |

27.9 |

16.13 |

| CH508 |

32 |

73 |

152 |

179 |

195 |

12.73 |

1.25 |

50.8 |

31.75 |

13.46 |

51.7 |

30.9 |

14.35 |

| CH571 |

60 |

138 |

287 |

306 |

333 |

12.5 |

2.29 |

57.15 |

26.39 |

15.24 |

58 |

25.6 |

16.1 |

| CH572 |

33 |

75 |

156 |

185 |

200 |

14.3 |

1.444 |

57.15 |

35.56 |

13.97 |

58 |

34.7 |

14.86 |

| CH610 |

|

192 |

400 |

|

|

14.37 |

3.675 |

62 |

32.6 |

25 |

63.1 |

31.37 |

26.27 |

| CH740 |

|

206 |

429 |

|

|

18.38 |

5.04 |

74.1 |

45.3 |

35 |

75.2 |

44.07 |

36.27 |

| CH777 |

30 |

68 |

142 |

|

|

20 |

1.77 |

77.8 |

49.23 |

12.7 |

78.9 |

48 |

13.97 |

| CH778 |

37 |

85 |

178 |

|

|

20 |

2.27 |

77.8 |

49.23 |

15.9 |

78.9 |

48 |

17.02 |

| CH1013 |

40 |

92 |

192 |

|

|

24.27 |

2.97 |

101.6 |

57.2 |

13.6 |

103.1 |

55.7 |

14.9 |

| CH1016 |

47 |

112 |

228 |

|

|

24.27 |

3.52 |

101.6 |

57.2 |

16.5 |

103.1 |

55.7 |

17.8 |

| CH1027 |

80 |

184 |

384 |

|

|

24.27 |

5.94 |

101.6 |

57.2 |

27.2 |

103.1 |

55.7 |

28.5 |

| CH1033 |

94 |

224 |

456 |

|

|

24.27 |

7.04 |

101.6 |

57.2 |

33 |

103.1 |

55.7 |

34.3 |

| CH1320 |

54 |

124 |

259 |

|

|

32.42 |

5.35 |

132.5 |

78.6 |

20.3 |

134.2 |

77 |

21.7 |

| CH1325 |

68 |

156 |

325 |

|

|

32.42 |

6.71 |

132.5 |

78.6 |

25.4 |

134.2 |

77 |

26.8 |

| CH1333 |

88 |

202 |

422 |

|

|

32.42 |

8.72 |

132.5 |

78.6 |

33 |

134.2 |

77 |

34.4 |

| CH1340 |

108 |

248 |

518 |

|

|

32.42 |

10.69 |

132.5 |

78.6 |

40.6 |

134.2 |

77 |

42 |

| CH1625 |

80 |

184 |

384 |

|

|

38.65 |

9.46 |

165 |

88.9 |

25.4 |

167.2 |

86.9 |

27.3 |

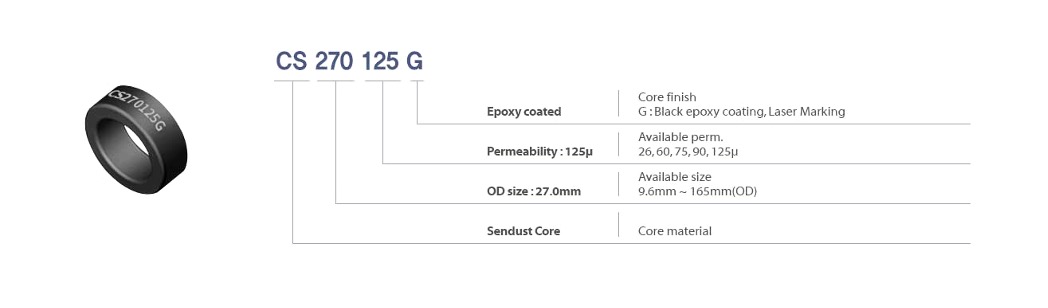

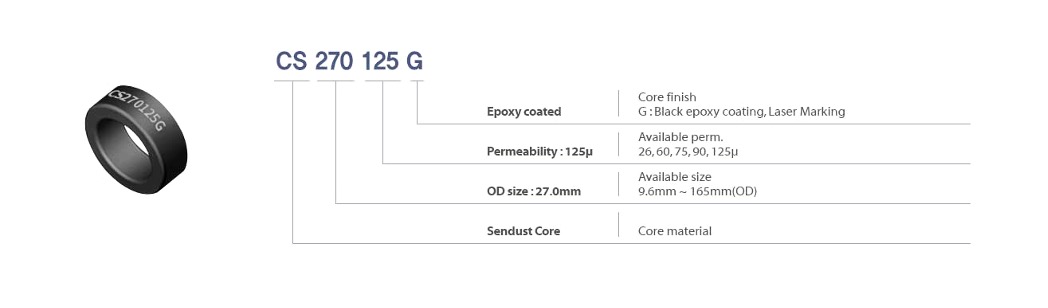

Sendust Cores

-

Characteristics:

Fe-Si-Al alloy

Near-zero magnetostriction, good audible noise remover

Good core loss performance vs. iron powder cores

Low cost compares with other magnetic powder cores

-

Applications:

PFC circuits, Switching regulator inductors, In-line noise filters, Pulse transformers, flyback transformers

| Part No |

Nominal Inductance(nH/N²) |

Path Length (cm) |

Cross Section Area (cm²) |

Dimensions(mm) |

| Before Finish Dimensions |

After Finish Dimensions |

| OD(mm) |

ID(mm) |

HT(mm) |

OD(mm) |

ID(mm) |

HT(mm) |

| 26 |

60 |

75 |

90 |

125 |

MAX |

MIN |

MAX |

MAX |

MIN |

MAX |

| CS096 |

11 |

25 |

32 |

38 |

53 |

2.18 |

0.075 |

9.65 |

4.78 |

3.18 |

10.29 |

4.27 |

3.81 |

| CS097 |

14 |

32 |

40 |

48 |

66 |

2.18 |

0.095 |

9.65 |

4.78 |

3.96 |

10.29 |

4.27 |

4.57 |

| CS102 |

14 |

32 |

40 |

48 |

66 |

2.38 |

0.1 |

10.16 |

5.08 |

3.96 |

10.8 |

4.57 |

4.57 |

| CS112 |

11 |

26 |

32 |

38 |

53 |

2.69 |

0.091 |

11.18 |

6.35 |

3.96 |

11.9 |

5.89 |

4.72 |

| CS127 |

12 |

27 |

34 |

40 |

56 |

3.12 |

0.114 |

12.7 |

7.62 |

4.75 |

13.46 |

6.99 |

5.51 |

| CS166 |

15 |

35 |

43 |

52 |

72 |

4.11 |

0.192 |

16.51 |

10.16 |

6.35 |

17.4 |

9.53 |

7.11 |

| CS172 |

19 |

43 |

53 |

64 |

89 |

4.14 |

0.232 |

17.27 |

9.65 |

6.35 |

18.03 |

9.02 |

7.11 |

| CS203 |

14 |

32 |

41 |

49 |

68 |

5.09 |

0.226 |

20.32 |

12.7 |

6.35 |

21.1 |

12.07 |

7.11 |

| CS229 |

19 |

43 |

54 |

65 |

90 |

5.67 |

0.331 |

22.86 |

13.97 |

7.62 |

23.62 |

13.39 |

8.38 |

| CS234 |

22 |

51 |

63 |

76 |

105 |

5.88 |

0.388 |

23.57 |

14.4 |

8.89 |

24.3 |

13.77 |

9.7 |

| CS270 |

32 |

75 |

94 |

113 |

157 |

6.35 |

0.654 |

26.92 |

14.73 |

11.18 |

27.7 |

14.1 |

11.99 |

| CS330 |

28 |

61 |

76 |

91 |

127 |

8.15 |

0.672 |

33.02 |

19.94 |

10.67 |

33.83 |

19.3 |

11.61 |

| CS343 |

16 |

38 |

47 |

57 |

79 |

8.95 |

0.454 |

34.29 |

23.37 |

8.89 |

35.2 |

22.6 |

9.83 |

| CS358 |

24 |

56 |

70 |

84 |

117 |

8.98 |

0.678 |

35.81 |

22.35 |

10.46 |

36.7 |

21.5 |

11.28 |

| CS400 |

35 |

81 |

101 |

121 |

168 |

9.84 |

1.072 |

39.88 |

24.13 |

14.48 |

40.7 |

23.3 |

15.37 |

| CS467 |

59 |

135 |

169 |

202 |

281 |

10.74 |

1.99 |

46.74 |

24.13 |

18.03 |

47.6 |

23.3 |

18.92 |

| CS468 |

37 |

86 |

107 |

128 |

178 |

11.63 |

1.34 |

46.74 |

28.7 |

15.24 |

47.6 |

27.9 |

16.13 |

| CS508 |

32 |

73 |

91 |

109 |

152 |

12.73 |

1.25 |

50.8 |

31.75 |

13.46 |

51.7 |

30.9 |

14.35 |

| CS571 |

60 |

138 |

172 |

206 |

287 |

12.5 |

2.29 |

57.15 |

26.39 |

15.24 |

58 |

25.6 |

16.1 |

| CS572 |

33 |

75 |

94 |

112 |

156 |

14.3 |

1.444 |

57.15 |

35.56 |

13.97 |

58 |

34.7 |

14.86 |

| CS610 |

83 |

192 |

240 |

288 |

400 |

14.37 |

3.675 |

62 |

32.6 |

25 |

63.1 |

31.37 |

26.27 |

| CS740 |

89 |

206 |

257 |

309 |

429 |

18.38 |

5.04 |

74.1 |

45.3 |

35 |

75.2 |

44.07 |

36.27 |

| CS777 |

30 |

68 |

85 |

102 |

124 |

20 |

1.77 |

77.8 |

49.23 |

12.7 |

78.9 |

48 |

13.97 |

| CS778 |

37 |

85 |

107 |

128 |

178 |

20 |

2.27 |

77.8 |

49.23 |

15.9 |

78.9 |

48 |

17.02 |

| CS1013 |

40 |

92 |

115 |

138 |

445 |

24.27 |

2.97 |

101.6 |

57.2 |

13.6 |

103.1 |

55.7 |

14.9 |

| CS1016 |

47 |

112 |

137 |

134 |

540 |

24.27 |

3.52 |

101.6 |

57.2 |

16.5 |

103.1 |

55.7 |

17.8 |

| CS1027 |

80 |

184 |

231 |

277 |

890 |

24.27 |

5.94 |

101.6 |

57.2 |

27.2 |

103.1 |

55.7 |

28.5 |

| CS1033 |

94 |

224 |

273 |

328 |

1080 |

24.27 |

7.04 |

101.6 |

57.2 |

33 |

103.1 |

55.7 |

34.3 |

| CS1320 |

54 |

124 |

155 |

186 |

1064 |

32.42 |

5.35 |

132.5 |

78.6 |

20.3 |

134.2 |

77 |

21.7 |

| CS1325 |

68 |

156 |

195 |

234 |

1332 |

32.42 |

6.71 |

132.5 |

78.6 |

25.4 |

134.2 |

77 |

26.8 |

| CS1333 |

88 |

202 |

253 |

304 |

1730 |

32.42 |

8.72 |

132.5 |

78.6 |

33 |

134.2 |

77 |

34.4 |

| CS1340 |

108 |

248 |

311 |

373 |

2128 |

32.42 |

10.69 |

132.5 |

78.6 |

40.6 |

134.2 |

77 |

42 |

| CS1625 |

80 |

184 |

230 |

277 |

2280 |

38.65 |

9.46 |

165 |

88.9 |

25.4 |

167.2 |

86.9 |

27.3 |

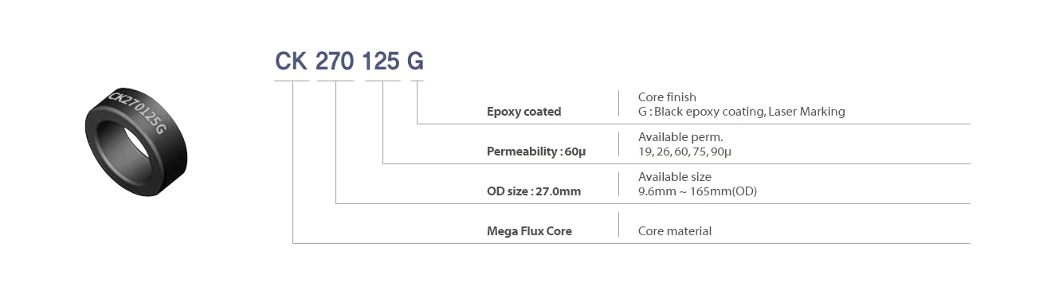

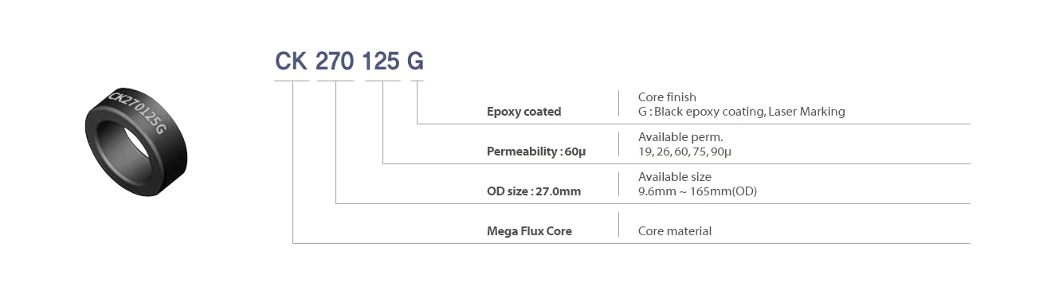

Mega Flux Cores

-

Characteristics:

Fe-Si alloy

High current and energy storage capability (up to 16,000 Gauss saturation level)

Excellent DC bias (DCB) characteristics, but lower in cost than High Flux cores

High Curie Temperature (700C), excellent thermal properties

-

Applications:

Buck/boost inductors, High power systems, inverters and reactors for electric vehicles (EV) and solar industry.

| Part No |

Nominal Inductance(nH/N²) |

Path Length (cm) |

Cross Section Area (cm²) |

Dimensions(mm) |

| Before Finish Dimensions |

After Finish Dimensions |

| OD(mm) |

ID(mm) |

HT(mm) |

OD(mm) |

ID(mm) |

HT(mm) |

| 19 |

26 |

60 |

75 |

90 |

MAX |

MIN |

MAX |

MAX |

MIN |

MAX |

| CK096 |

|

11 |

25 |

31 |

38 |

2.18 |

0.075 |

9.65 |

4.78 |

3.18 |

10.29 |

4.27 |

3.81 |

| CK097 |

|

14 |

32 |

40 |

48 |

2.18 |

0.095 |

9.65 |

4.78 |

3.96 |

10.29 |

4.27 |

4.57 |

| CK112 |

|

11 |

26 |

32 |

38 |

2.69 |

0.091 |

11.18 |

6.35 |

3.96 |

11.9 |

5.89 |

4.72 |

| CK127 |

|

12 |

27 |

34 |

40 |

3.12 |

0.114 |

12.7 |

7.62 |

4.75 |

13.46 |

6.99 |

5.51 |

| CK166 |

|

15 |

35 |

43 |

52 |

4.11 |

0.192 |

16.51 |

10.16 |

6.35 |

17.4 |

9.53 |

7.11 |

| CK172 |

|

19 |

43 |

53 |

64 |

4.14 |

0.232 |

17.27 |

9.65 |

6.35 |

18.03 |

9.02 |

7.11 |

| CK203 |

|

14 |

32 |

41 |

49 |

5.09 |

0.226 |

20.32 |

12.7 |

6.35 |

21.1 |

12.07 |

7.11 |

| CK229 |

|

19 |

43 |

54 |

65 |

5.67 |

0.331 |

22.86 |

13.97 |

7.62 |

23.62 |

13.39 |

8.38 |

| CK234 |

16 |

22 |

51 |

63 |

76 |

5.88 |

0.388 |

23.57 |

14.4 |

8.89 |

24.3 |

13.77 |

9.7 |

| CK270 |

24 |

32 |

75 |

94 |

113 |

6.35 |

0.654 |

26.92 |

14.73 |

11.18 |

27.7 |

14.1 |

11.99 |

| CK330 |

19 |

28 |

61 |

76 |

91 |

8.15 |

0.672 |

33.02 |

19.94 |

10.67 |

33.83 |

19.3 |

11.61 |

| CK343 |

12 |

16 |

38 |

47 |

57 |

8.95 |

0.454 |

34.29 |

23.37 |

8.89 |

35.2 |

22.6 |

9.83 |

| CK358 |

18 |

24 |

56 |

70 |

84 |

8.98 |

0.678 |

35.81 |

22.35 |

10.46 |

36.7 |

21.5 |

11.28 |

| CK400 |

26 |

35 |

81 |

101 |

121 |

9.84 |

1.072 |

39.88 |

24.13 |

14.48 |

40.7 |

23.3 |

15.37 |

| CK467 |

43 |

59 |

135 |

169 |

202 |

10.74 |

1.99 |

46.74 |

24.13 |

18.03 |

47.6 |

23.3 |

18.92 |

| CK468 |

27 |

37 |

86 |

107 |

128 |

11.63 |

1.34 |

46.74 |

28.7 |

15.24 |

47.6 |

27.9 |

16.13 |

| CK508 |

23 |

32 |

73 |

91 |

109 |

12.73 |

1.25 |

50.8 |

31.75 |

13.46 |

51.7 |

30.9 |

14.35 |

| CK571 |

44 |

|

138 |

172 |

206 |

12.5 |

2.29 |

57.15 |

26.39 |

15.24 |

58 |

25.6 |

16.1 |

| CK572 |

24 |

|

75 |

94 |

112 |

14.3 |

1.444 |

57.15 |

35.56 |

13.97 |

58 |

34.7 |

14.86 |

| CK610 |

61 |

83 |

192 |

240 |

|

14.37 |

3.675 |

62 |

32.6 |

25 |

63.1 |

31.37 |

26.27 |

| CK740 |

65 |

89 |

206 |

257 |

309 |

18.38 |

5.04 |

74.1 |

45.3 |

35 |

75.2 |

44.07 |

36.27 |

| CK777 |

22 |

30 |

68 |

85 |

102 |

20 |

1.77 |

77.8 |

49.23 |

12.7 |

78.9 |

48 |

13.97 |

| CK778 |

27 |

37 |

|

107 |

128 |

20 |

2.77 |

77.8 |

49.23 |

15.9 |

78.9 |

48 |

17.02 |

| CK1013 |

29 |

40 |

92 |

192 |

|

24.27 |

2.97 |

101.6 |

57.2 |

13.6 |

103.1 |

55.7 |

14.9 |

| CK1016 |

35 |

47 |

112 |

228 |

|

24.27 |

3.52 |

101.6 |

57.2 |

16.5 |

103.1 |

55.7 |

17.8 |

| CK1027 |

58 |

80 |

184 |

384 |

|

24.27 |

5.94 |

101.6 |

57.2 |

27.2 |

103.1 |

55.7 |

28.5 |

| CK1033 |

70 |

94 |

224 |

456 |

|

24.27 |

7.04 |

101.6 |

57.2 |

33 |

103.1 |

55.7 |

34.3 |

| CK1320 |

39 |

54 |

124 |

259 |

|

32.42 |

5.35 |

132.5 |

78.6 |

20.3 |

134.2 |

77 |

21.7 |

| CK1325 |

49 |

68 |

156 |

325 |

|

32.42 |

6.71 |

132.5 |

78.6 |

25.4 |

134.2 |

77 |

26.8 |

| CK1333 |

64 |

88 |

202 |

422 |

|

32.42 |

8.72 |

132.5 |

78.6 |

33 |

134.2 |

77 |

34.4 |

| CK1340 |

79 |

108 |

248 |

518 |

|

32.42 |

10.69 |

132.5 |

78.6 |

40.6 |

134.2 |

77 |

42 |

| CK1625 |

58 |

80 |

184 |

384 |

|

38.65 |

9.46 |

165 |

88.9 |

25.4 |

167.2 |

86.9 |

27.3 |

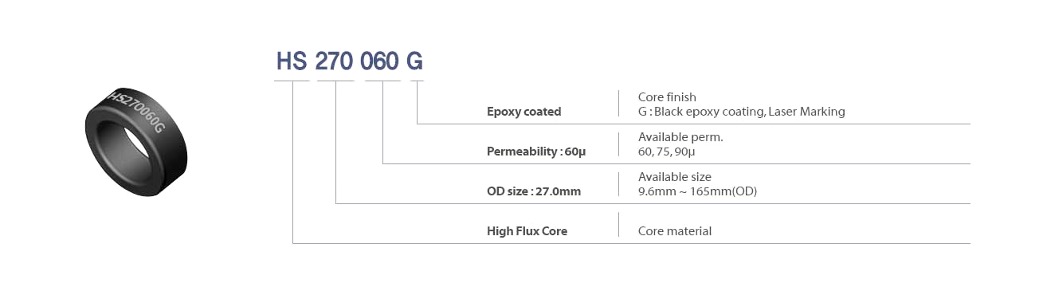

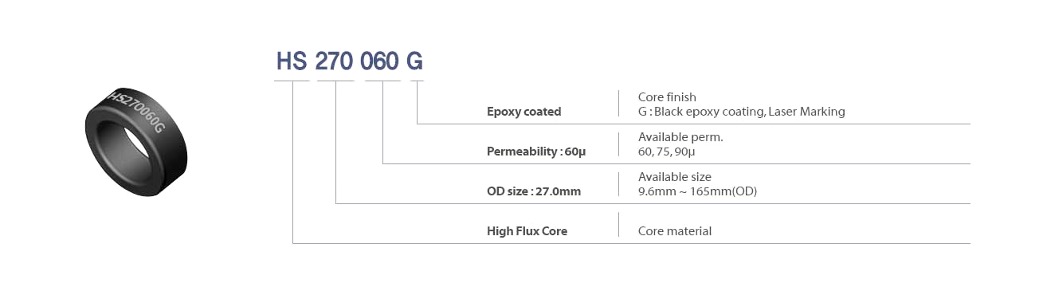

HS Cores

-

Characteristics:

Fe-Ni-Si-Al alloy

Good DC bias performance and low core loss

Excellent thermal stability

Good alternative to the amorphous cores (APH cores)

-

Applications:

High-power Desktop PCs, Server PCs, Automotive and Solar power generation

| Part No |

Nominal Inductance(nH/N²) |

Path Length (cm) |

Cross Section Area (cm²) |

Dimensions(mm) |

| Before Finish Dimensions |

After Finish Dimensions |

| OD(mm) |

ID(mm) |

HT(mm) |

OD(mm) |

ID(mm) |

HT(mm) |

| 60 |

75 |

90 |

MAX |

MIN |

MAX |

MAX |

MIN |

MAX |

| HS096 |

25 |

32 |

38 |

2.18 |

0.075 |

9.65 |

4.78 |

3.18 |

10.29 |

4.27 |

3.81 |

| HS097 |

32 |

40 |

48 |

2.18 |

0.095 |

9.65 |

4.78 |

3.96 |

10.29 |

4.27 |

4.57 |

| HS102 |

32 |

40 |

48 |

2.38 |

0.1 |

10.16 |

5.08 |

3.96 |

10.8 |

4.57 |

4.57 |

| HS112 |

26 |

32 |

38 |

2.69 |

0.091 |

11.18 |

6.35 |

3.96 |

11.9 |

5.89 |

4.72 |

| HS127 |

27 |

34 |

40 |

3.12 |

0.114 |

12.7 |

7.62 |

4.75 |

13.46 |

6.99 |

5.51 |

| HS166 |

35 |

43 |

52 |

4.11 |

0.192 |

16.51 |

10.16 |

6.35 |

17.4 |

9.53 |

7.11 |

| HS172 |

43 |

53 |

64 |

4.14 |

0.232 |

17.27 |

9.65 |

6.35 |

18.03 |

9.02 |

7.11 |

| HS203 |

32 |

41 |

49 |

5.09 |

0.226 |

20.32 |

12.7 |

6.35 |

21.1 |

12.07 |

7.11 |

| HS229 |

43 |

54 |

65 |

5.67 |

0.331 |

22.86 |

13.97 |

7.62 |

23.62 |

13.39 |

8.38 |

| HS234 |

51 |

63 |

76 |

5.88 |

0.388 |

23.57 |

14.4 |

8.89 |

24.3 |

13.77 |

9.7 |

| HS270 |

75 |

94 |

113 |

6.35 |

0.654 |

26.92 |

14.73 |

11.18 |

27.7 |

14.1 |

11.99 |

| HS330 |

61 |

76 |

91 |

8.15 |

0.672 |

33.02 |

19.94 |

10.67 |

33.83 |

19.3 |

11.61 |

| HS343 |

38 |

47 |

57 |

8.95 |

0.454 |

34.29 |

23.37 |

8.89 |

35.2 |

22.6 |

9.83 |

| HS358 |

56 |

70 |

84 |

8.98 |

0.678 |

35.81 |

22.35 |

10.46 |

36.7 |

21.5 |

11.28 |

| HS400 |

81 |

101 |

121 |

9.84 |

1.072 |

39.88 |

24.13 |

14.48 |

40.7 |

23.3 |

15.37 |

| HS467 |

135 |

169 |

202 |

10.74 |

1.99 |

46.74 |

24.13 |

18.03 |

47.6 |

23.3 |

18.92 |

| HS468 |

86 |

107 |

128 |

11.63 |

1.34 |

46.74 |

28.7 |

15.24 |

47.6 |

27.9 |

16.13 |

| HS508 |

73 |

91 |

109 |

12.73 |

1.25 |

50.8 |

31.75 |

13.46 |

51.7 |

30.9 |

14.35 |

| HS571 |

138 |

172 |

206 |

12.5 |

2.29 |

57.15 |

26.39 |

15.24 |

58 |

25.6 |

16.1 |

| HS572 |

75 |

94 |

112 |

14.3 |

1.444 |

57.15 |

35.56 |

13.97 |

58 |

34.7 |

14.86 |

| HS610 |

192 |

240 |

288 |

14.37 |

3.675 |

62 |

32.6 |

25 |

63.1 |

31.37 |

26.27 |

| HS740 |

206 |

257 |

309 |

18.38 |

5.04 |

74.1 |

45.3 |

35 |

75.2 |

44.07 |

36.27 |

| HS777 |

68 |

85 |

102 |

20 |

1.77 |

77.8 |

49.23 |

12.7 |

78.9 |

48 |

13.97 |

| HS778 |

85 |

107 |

128 |

20 |

2.27 |

77.8 |

49.23 |

15.9 |

78.9 |

48 |

17.02 |

| HS1013 |

92 |

|

|

24.27 |

2.972 |

101.6 |

57.2 |

13.6 |

103.1 |

55.7 |

14.9 |

| HS1016 |

112 |

|

|

24.27 |

3.522 |

101.6 |

57.2 |

16.5 |

103.1 |

55.7 |

17.8 |

| HS1027 |

184 |

|

|

24.27 |

5.944 |

101.6 |

57.2 |

27.2 |

103.1 |

55.7 |

28.5 |

| HS1033 |

224 |

|

|

24.27 |

7.044 |

101.6 |

57.2 |

33 |

103.1 |

55.7 |

34.3 |

| HS1320 |

124 |

|

|

32.42 |

5.347 |

132.5 |

78.6 |

20.3 |

134.2 |

77 |

21.7 |

| HS1325 |

156 |

|

|

32.42 |

6.71 |

132.5 |

78.6 |

25.4 |

134.2 |

77 |

26.8 |

| HS1333 |

202 |

|

|

32.42 |

8.717 |

132.5 |

78.6 |

33 |

134.2 |

77 |

34.4 |

| HS1340 |

248 |

|

|

32.42 |

10.69 |

132.5 |

78.6 |

40.6 |

134.2 |

77 |

42 |

| HS1625 |

184 |

|

|

38.65 |

9.46 |

165 |

88.9 |

25.4 |

167.2 |

86.9 |

27.3 |

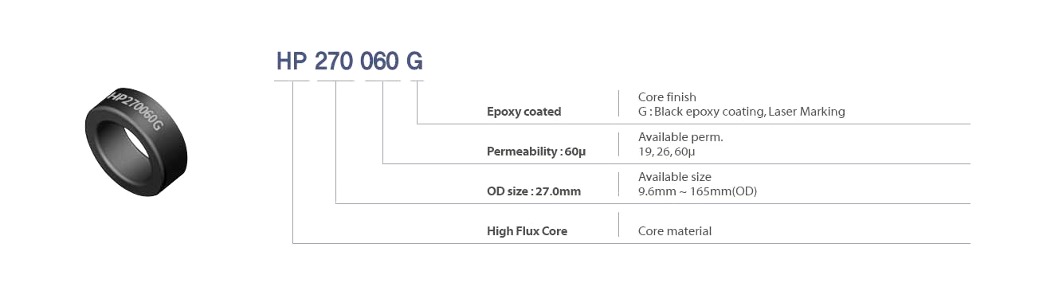

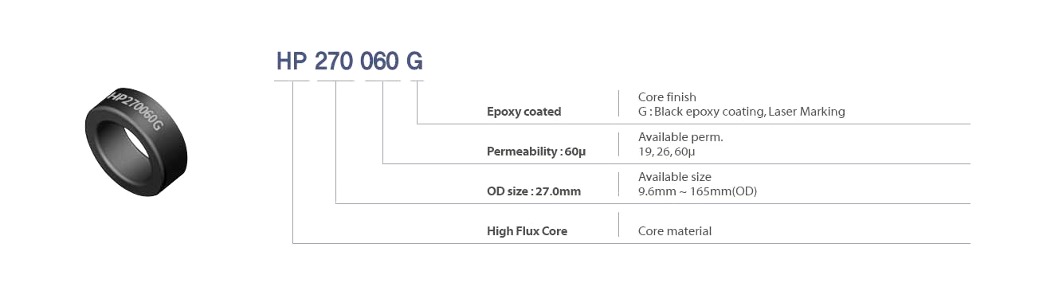

HP Cores

-

Characteristics:

Fe-Si-Al alloy (Gas Atomization process)

Near-zero magnetostriction, eliminate audible noise.

Perfect core loss performance at 19um and 26um permeability.

Minimize the temperature rise of high frequency devices.

Good alternative to the amorphous cores (APH cores)

-

Applications:

UPS, ESS, PFC and output inductors, small-medium power servers, EV chargers

| Part No |

Nominal Inductance(nH/N²) |

Path Length (cm) |

Cross Section Area (cm²) |

Dimensions(mm) |

| Before Finish Dimensions |

After Finish Dimensions |

| OD(mm) |

ID(mm) |

HT(mm) |

OD(mm) |

ID(mm) |

HT(mm) |

| 19 |

26 |

60 |

MAX |

MIN |

MAX |

MAX |

MIN |

MAX |

| HP096 |

|

11 |

25 |

2.18 |

0.075 |

9.65 |

4.78 |

3.18 |

10.29 |

4.27 |

3.81 |

| HP097 |

|

14 |

32 |

2.18 |

0.095 |

9.65 |

4.78 |

3.96 |

10.29 |

4.27 |

4.57 |

| HP102 |

|

14 |

32 |

2.38 |

0.1 |

10.16 |

5.08 |

3.96 |

10.8 |

4.57 |

4.57 |

| HP112 |

|

11 |

26 |

2.69 |

0.091 |

11.18 |

6.35 |

3.96 |

11.9 |

5.89 |

4.72 |

| HP127 |

|

12 |

27 |

3.12 |

0.114 |

12.7 |

7.62 |

4.75 |

13.46 |

6.99 |

5.51 |

| HP166 |

|

25 |

35 |

4.11 |

0.192 |

16.51 |

10.16 |

6.35 |

17.4 |

9.53 |

7.11 |

| HP172 |

|

19 |

43 |

4.14 |

0.232 |

17.27 |

9.65 |

6.35 |

18.03 |

9.02 |

7.11 |

| HP203 |

|

14 |

32 |

5.09 |

0.226 |

20.32 |

12.7 |

6.35 |

21.1 |

12.07 |

7.11 |

| HP229 |

|

19 |

43 |

5.67 |

0.331 |

22.86 |

13.97 |

7.62 |

23.62 |

13.39 |

8.38 |

| HP234 |

|

22 |

51 |

5.88 |

0.388 |

23.57 |

14.4 |

8.89 |

24.3 |

13.77 |

9.7 |

| HP270 |

24 |

33 |

75 |

6.35 |

0.654 |

26.92 |

14.73 |

11.18 |

27.7 |

14.1 |

11.99 |

| HP330 |

19 |

26 |

61 |

8.15 |

0.672 |

33.02 |

19.94 |

10.67 |

33.83 |

19.3 |

11.61 |

| HP343 |

12 |

16 |

38 |

8.95 |

0.454 |

34.29 |

23.37 |

8.89 |

35.2 |

22.6 |

9.83 |

| HP358 |

18 |

24 |

56 |

8.98 |

0.678 |

35.81 |

22.35 |

10.46 |

36.7 |

21.5 |

11.28 |

| HP400 |

26 |

35 |

81 |

9.84 |

1.072 |

39.88 |

24.13 |

14.48 |

40.7 |

23.3 |

15.37 |

| HP467 |

43 |

59 |

135 |

10.74 |

1.99 |

46.74 |

24.13 |

18.03 |

47.6 |

23.3 |

18.92 |

| HP468 |

27 |

37 |

86 |

11.63 |

1.34 |

46.74 |

28.7 |

15.24 |

47.6 |

27.9 |

16.13 |

| HP508 |

23 |

32 |

73 |

12.73 |

1.25 |

50.8 |

31.75 |

13.46 |

51.7 |

30.9 |

14.35 |

| HP571 |

44 |

60 |

138 |

12.5 |

2.29 |

57.15 |

26.39 |

15.24 |

58 |

25.6 |

16.1 |

| HP572 |

24 |

33 |

75 |

14.3 |

1.444 |

57.15 |

35.56 |

13.97 |

58 |

34.7 |

14.86 |

| HP610 |

61 |

83 |

|

14.37 |

3.675 |

62 |

32.6 |

25 |

63.1 |

31.37 |

26.27 |

| HP740 |

61 |

89 |

|

18.38 |

5.04 |

74.1 |

45.3 |

35 |

75.2 |

44.07 |

36.27 |

| HP777 |

22 |

29 |

|

20 |

1.77 |

77.8 |

49.23 |

12.7 |

78.9 |

48 |

13.97 |

| HP778 |

27 |

37 |

|

20 |

2.27 |

77.8 |

49.23 |

15.9 |

78.9 |

48 |

17.02 |

| HP1013 |

29 |

40 |

|

24.27 |

2.972 |

101.6 |

57.2 |

13.6 |

103.1 |

55.7 |

14.9 |

| HP1016 |

35 |

49 |

|

24.27 |

3.522 |

101.6 |

57.2 |

16.5 |

103.1 |

55.7 |

17.8 |

| HP1027 |

58 |

80 |

|

24.27 |

5.944 |

101.6 |

57.2 |

27.2 |

103.1 |

55.7 |

28.5 |

| HP1033 |

71 |

97 |

|

24.27 |

7.044 |

101.6 |

57.2 |

33 |

103.1 |

55.7 |

34.3 |

| HP1320 |

39 |

54 |

|

32.42 |

5.347 |

132.5 |

78.6 |

20.3 |

134.2 |

77 |

21.7 |

| HP1325 |

49 |

68 |

|

32.42 |

6.71 |

132.5 |

78.6 |

25.4 |

134.2 |

77 |

26.8 |

| HP1333 |

64 |

88 |

|

32.42 |

8.717 |

132.5 |

78.6 |

33 |

134.2 |

77 |

34.4 |

| HP1340 |

79 |

107 |

|

32.42 |

10.69 |

132.5 |

78.6 |

40.6 |

134.2 |

77 |

42 |

| HP1625 |

58 |

80 |

|

38.65 |

9.46 |

165 |

88.9 |

25.4 |

167.2 |

86.9 |

27.3 |